An engine must be lubricated for smooth, efficient performance, and an oiling system addresses this need. There are two main types of oiling systems, a wet sump and a dry sump.

The wet sump system is typical in most production cars, with the oil sitting in an oil pan reservoir stored beneath the crankshaft. An internal oil pump, which sucks the oil through a tube from the bottom of the pan’s sump, distributing oil throughout the engine. The wet sump system provides the advantage of a simple design, however there are potential issues regarding oil control particularly in modified engines and racing applications.

The large g-forces pulled under acceleration, aggressive braking and cornering at speed:

- cause the oil in the pan to gravitate away from the pumps pick-up tube, which will stave the system of oil and cause damage to the engine;

- cause the oil to slosh in the pan, creating a higher probability of the crankshaft slapping into the oil as it turns, whipping the oil into an aerated froth and reducing the oiling systems ability to create pressure; and

- each revolution of the crankshaft causes the parts to move rapidly through the oil and air in the pan, generating minute amounts of parasitic power loss caused by viscous drag and air drag (windage) negatively impacting horsepower

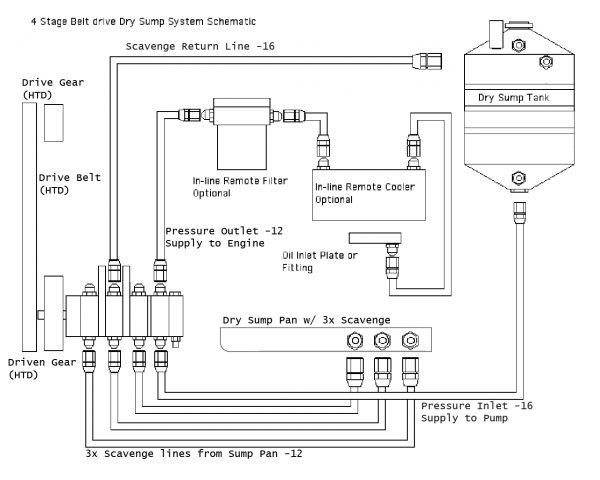

The alternative, a dry sump set-up, uses two or more oil pumps, and a separate oil reservoir. There are a minimum of two stages, one stage for pressure and at least one stage for scavenge. The pressure stage supplies oil from the bottom of the reservoir into the engine, and the scavenge stage/s remove oil out of the dry sump pan and return this oil (and air) to the reservoir, with the option for adding multiple scavenge stages to ensure maximum oil is scavenged from the engine. The reservoir (tank) controls the flow of oil, removing air bubbles, and sending the oil back to the oil pump to be routed through the engine.

In a dry sump set-up, the oil pump is usually mounted to the side of the engine, and driven by a belt off the front of the engine. It is typically lower than the reservoir, so it is gravity fed, rather than requiring a pump to suck the oil upward, as in the wet sump design, and performs more efficiently as it receives positive pressure on the suction side.

The dry sump set-up is more appropriate for a racing application, compared to the wet sump system, as it provides:

- improved reliability due to consistent oil pressure;

- the shallow oil pan allows the engine to be mounted lower in the chassis, effectively lowering the centre of gravity and provide flexibility to modify underfloor aerodynamics;

- the option to move the oil tank within the confines of the car to improve weight distribution;

- the option to increase oil capacity to be as large as you like;

- less chance of engine damage as no longer susceptible to starving the engine of oil due to movement issues caused by cornering or launching forces;

- protection against parasitic power loss as it keeps oil away from the crankshaft to reduce oil drag (viscous), and pulls out most the of air to reduce air drag (windage);

- cooler oil due to the external storage, plus additional cooling available by utilising an oil cooler, mounted inline between the pressure outlet and the engine; and

- easier maintenance, and replacement, as the pump is external to the engine.

The key documented disadvantage to a dry-sump setup is the added cost and complexity to your engine build, however, from the weekend enthusiast to the professional racer the significant advantages far out way the cost, remember no oil equals no engine!